EPIC™ HRSG Off-line Cleaning

EPIC – Extraction Pressure Impulse Cleaner

The EPIC Extraction Pressure Impulse Cleaner is revolutionizing HRSG Cleaning. This off-line cleaning technology uses safe, effective and directly targeted pressure-wave impulse cleaning energy to remove deposits deep within and throughout tube bundles. The patented cleaning procedure that is employed systematically concentrates its affect just to the fouled tube sections, with no indiscriminate blasting impact to the surrounding area, nor mechanical fatigue to the tubes, expansion joints or superstructure components.

How it Works

Adapted from GE’s jet propulsion technology over 12 years ago, the cleaning system has been used effectively for nearly a decade for on-line boiler cleaning including HRSGs. IMPULSE® pressure waves are generated in a controlled, pulsed manner, safely within a 2 inch system chamber to direct cleaning waves just into heat transfer surfaces to which debris has become adhered. EPIC utilizes pressure waves to create a high amplitude particle displacement to resonate and dislodge particulate deposits. The intense shock waves approach and encompass tube surfaces, transition around to back side, reconnect, and continue traveling. When the shock waves reach the heat transfer surface, they fracture deposits and dislodge the buildup. This method allows for a very targeted, deep, penetrating and encompassing 360° cleaning so heat transfer efficiency can be restored.

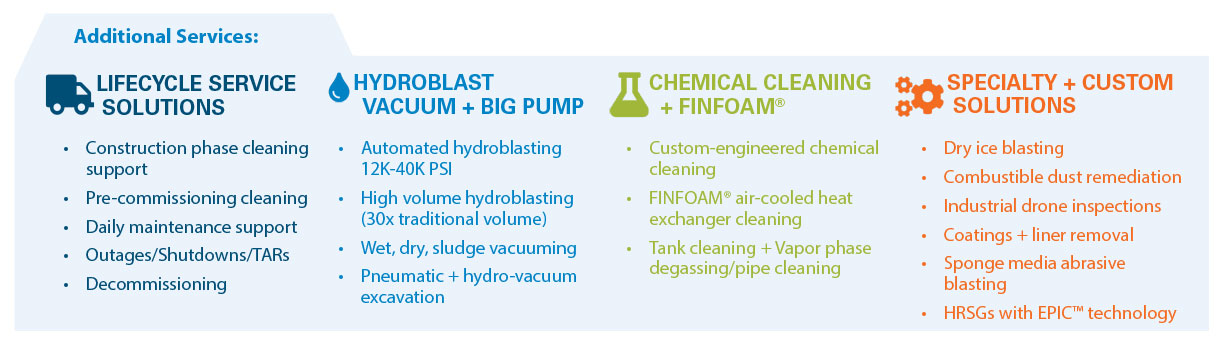

Benefits

Targeted impulses create deep, penetrating + encompassing 360°cleaning

No mechanical integrity damage to tubes or entire structure

No mechanical tube stretching or spreading required

Energy is directionally controlled through the tube bundle (i.e. no violentshock or indiscriminate blast impact to entire HRSG structure)

No scaffolding required

Reduced outage time compared to alternative methods

BEFOREEPIC™ and IMPULSE® are the property of PowerPlus Cleaning Systems, Inc. KBH Thompson proudly executes the EPIC technology in the field.

Before

L.P. economizer deposits on finned tubes.

After

Finned tubes after EPIC cleaning.

Improving HRSG Performance + Efficiency

Improving HRSG Performance + Efficiency

Over time, finned tubes in HRSGs can become excessively fouled due to combustion-side deposit formation, most commonly with rust caused by dew point, or ammonia salts transporting downstream of the SCR as well as off-line condensation, especially at the LP economizer cold end. Fouled HRSG tubes penalize plant performance in several ways such as decreasing heat rate by reducing the heat transfer and increasing back pressure of the gas turbine. Reduced heat transfer efficiency also reduces the net output of the steam turbine and increases exit stack temperature. This results in extra cost and lost revenue from restrictive output and/or reduction in steam generation.

HRSG cleaning is an effective way to restore lost performance thereby increasing the net power output. However, extreme caution choosing the HRSG cleaning methodology should be employed to consider the potential long term secondary mechanical effects on the tube integrity, welds, superstructure and duct work impact of the method selected.

The EPIC cleaning system, with safe, targeted, isolated and controlled cleaning pressure will not subject the HRSG to these adverse effects.

Why EPIC Over Other Methods

Safe for Your Entire Unit

EPIC’s impulses are highly targeted through the tube bundle and do not cause any damage to the mechanical integrity of the tubes. Plus, there is no violent shock or indiscriminate blast impact to the HRSG structure. In addition, the tubes will never be stretched or spread and the process has several fail-safe safety features.

No Pre-Cleaning Work

No scaffolding is required nor tube spreading, or other modifications are necessary (or minimal if any) to gain access for cleaning. Exceptionally limited site support resources are needed.

Reduced Cleaning Time

Utilizing the advanced EPIC technology, with remote positioning and activation of the IMPULSE cleaning equipment with real time video monitoring of the cleaning in action, results in reduced overall outage duration as well as confined space exposure compared to several other methods. The service is also complemented by the post-cleaning removal of the considerable dislodged debris by incorporating KBH Thompson’s own vacuuming equipment and personnel, rather than orchestrating additional arrangements with yet another contractor for the turnkey HRSG cleaning project.

Trusted By Our Clients